HXGK全系列光纤涂覆机技术指南【2025修订版(双语)】

致尊敬的客户:

您好!

鉴于我司内销、外贸业务的持续增长,各类产品销量屡创新高,我们特此对各产品的技术文档进行了全面梳理与更新,并翻译成英文、日文、越南语、俄语、阿拉伯语及德语等多个语种,以满足不同国家和地区客户的需求。

为便于阅读,本公众号将先行发布中文与英文版本。如您对其他语种版本有查阅需求,敬请联系我们的客服团队进行索取。我们将竭诚为您提供所需资料,感谢您的理解与支持!

To Our Esteemed Clients:

Hello!

Due to the continuous growth of our foreign trade business and the increasing sales of our various products, we have comprehensively updated the technical documentation for each product and translated them into multiple languages including English, Japanese, Vietnamese, Russian, Arabic, and German.

For your convenience, we will first release the Chinese and English versions on this official account. If you need versions in other languages, please contact our customer service team. We will be happy to serve you and appreciate your understanding and support!

光纤涂覆机系列产品综述2025年,潍坊华纤光电科技有限公司对光纤涂覆机产品线进行了全面升级,隆重推出五大系列光纤涂覆机。这些产品广泛适用于常规光纤、特种光纤、荧光光纤、发光光纤及多种细小纤维等新型材料的涂覆需求,技术层面处于国际领先地位。

第一大系列为单模组光纤涂覆机,精准高效。

第二大系列是双模组光纤涂覆机,性能卓越。

第三大系列为双路注胶系统光纤涂覆机,作为出口级精品,配备双系统备份与固态封装技术,设计实现10年免维护,使用安心无忧。

第四大系列是特殊用途光纤涂覆机,涵盖小型化、户外便携带电池、模组分离式、极细纤维飞模对准式等多种定制方案,满足特定需求。

第五大系列则专注于进口涂覆机的维修与升级改造服务,专业可靠。

光纤涂覆机控制方式多样,包括全自动模式、半自动模式以及全自动/半自动混合模式,灵活便捷。

全系标配:光纤气动吸附、长寿命LED、紫外固化、兼容高、低折射率胶水及荧光胶水、双层石英模组更结实、加厚镀“金”石英玻璃更耐磨。

光纤涂覆长度选择丰富,涵盖(超短)20mm、(短)25mm、(常规)54mm、(长)108mm、(超长)150mm等多种规格。

光纤再涂覆直径:从180um至1000um,具体包括180um、200um、280um、300um、400um、430um、450um、560um、600um、670um、700um、860um、900um及1000um等多种选项。

光纤再涂覆形状:以圆形为主,同时也提供方形、带状、中间细两头粗等异形光纤的定制服务,满足客户多样化需求。

涂覆精度高:全系实现线性注胶,胶水沿槽流动,不大量外溢。涂覆外观干净、圆润无“船扣”,无气泡、无飞边、无毛刺;

第一大系列:单模组光纤涂覆机(平替藤仓、vytran)作为我司自主研发的核心产品,单模组光纤涂覆机是一款具备高精度、高产能特性的通用型工业级设备,专为光纤制造产线的规模化生产场景设计。凭借先进的涂覆工艺控制系统与精密机械结构,配合智能伺服驱动系统,具备高精度涂覆与高速生产优势,单根光纤涂覆效率较传统设备提升 30% 以上,有效保障产线高效稳定运行。

在产品矩阵构建上,我司提供覆盖全应用场景的型号体系:54mm 与 108mm 模组采用国际标准设计,对藤仓、Vytran 等进口品牌同类产品,实现国产化 替代与性能升级;同时,创新性推出行业领先的 20mm 超短模组与 150mm 超长模组,前者突破空间限制,适用于微型化光器件制造,后者则满足特种光纤的超长涂覆需求,为通信、传感、激光等领域提供定制化解决方案。

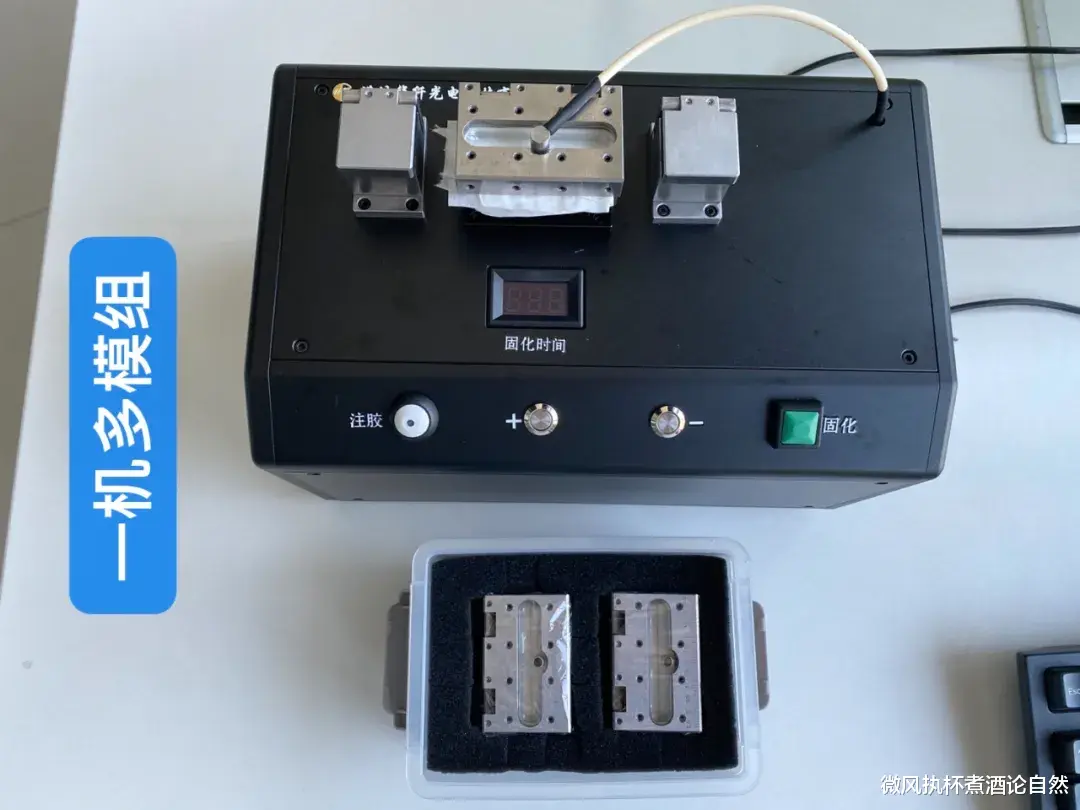

1、超短模组光纤涂覆机HXGK-T01(D20)(首发技术)

模组长度20mm,有效再涂覆长度0-20mm。再涂覆直径180um-1000um任选1种。

2.短模组光纤涂覆机HXGK-T01(D25)(首发技术)

模组长度25mm,有效再涂覆长度0-24mm。再涂覆直径180um-1000um任选1种。

3.常规模组光纤涂覆机HXGK-T01。

模组长度54mm,有效再涂覆长度0-50mm。再涂覆直径180um-1000um可任选1种。

4.长模组光纤涂覆机HXGK-T01(L)。

模组长度108mm,有效再涂覆长度0mm-100mm。再涂覆直径180um-1000um可任选1种。

5.超长模组光纤涂覆机HXGK-T150MM

模组长度156mm,有效再涂覆长度0mm-150mm。再涂覆直径180um-1000um可任选1种。

6.一机多模组。

单模组光纤涂覆机也可采用一机多模的方式,就是一台主机配置多个模组,使用的时候需手动更换所需的模组整体组件。再涂覆直径180um-1000um可任选多种。

双模组光纤涂覆机是我司自主研发的新型光纤涂覆机,该设备采用高度集成化设计,在一套主机上集成双涂覆模组与双注胶系统,支持多种工艺组合方案,满足光纤涂覆的多样化需求:

两种胶水一起用

设备可以同时安装并使用低折射率和高折射率的胶水,无需清洗管路,直接交替使用

粗细光纤都能涂

设备可搭配两种规格的涂覆模组,能快速切换涂不同粗细的光纤,单模光纤、多模、特种光纤都能涂。

两种长度涂层灵活选

设备可搭配两种长度的涂覆模组。能自动匹配涂覆长度。

内外两层涂层一起做

可用于双层涂覆,采用细芯模组(侧重折射率匹配)与粗芯模组(侧重机械强度)的级联结构,实现内层低折射柔性胶水与外层高折射刚性胶水的同步复合涂覆,或采用常规折射率内层+高模量韧性外层的增强型结构。

各种规格模组随便选

设备提供了各种规格的涂覆模组(180到1000微米都有)和不同折射率的胶水,满足不同客户的需求。

特殊模组也能定制

支持定制,比如中间细两头粗的、非对称芯径模组(如沙漏型)、单边涂覆模组、微结构图案化模组等定制化方案等。

1、短模组光纤涂覆机HXGK-T02(D)。

一套主机配置两套模组,长度均为25mm,有效再涂覆长度0mm-24mm。再涂覆直径180um-1000um可任选2种。

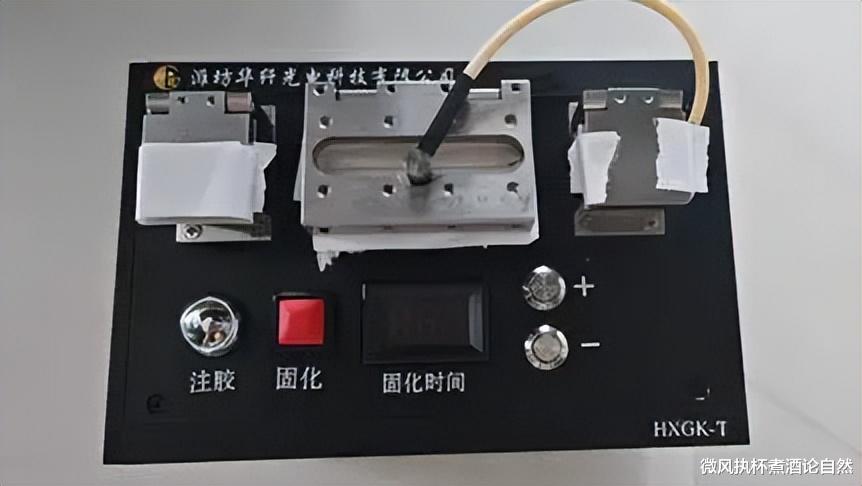

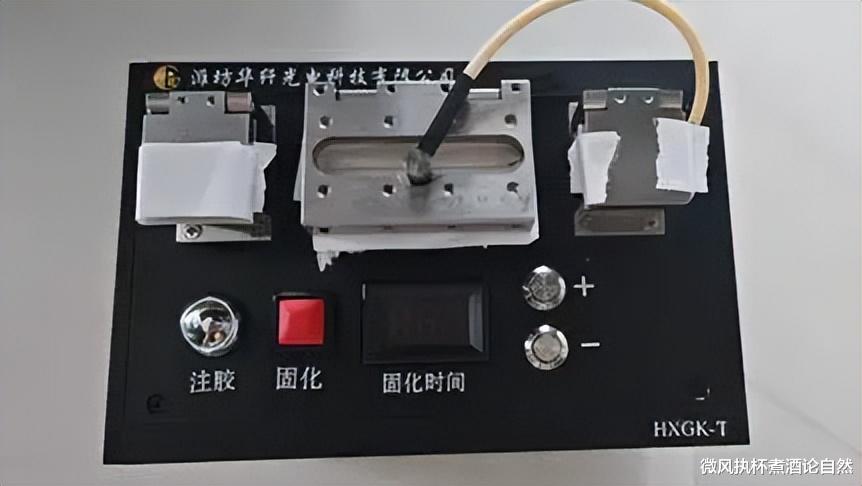

2、常规模组光纤涂覆机HXGK-T02。

一套主机配置两套模组,长度均为54mm,有效再涂覆长度0mm-50mm。再涂覆直径180um-1000um可任选2种。

3、长模组光纤涂覆机HXGK-T02(L)。

一套主机配置两套模组,长度均为108mm,有效再涂覆长度0mm-100mm。再涂覆直径180um-1000um可任选2种。

4、混合模组光纤涂覆机HXGK-T02(LD)。

一套主机配置两套模组,长度20mm、25mm、54mm、108mm可任选2种。再涂覆直径180um-1000um可任选2种。

潍坊华纤光电科技有限公司正式发布全球首款多型号双路注胶系统光纤涂覆机(型号:HXGK-ST06/HXGK-T150MM超长定制/HXGK-T02DIN),以自主核心技术打破行业壁垒,重新定义光纤涂覆工艺标准。作为出口级精品,配备双系统备份与固态封装技术,设计实现10年免维护,使用安心无忧。

1、旗舰机型:HXGK-ST06

全球首创双路注胶系统:独立双通道支持A/B胶水即换即用,免清洗、零停机,单台设备实现双倍产能,兼容实验室与量产需求。

场景化深度适配:专为光纤熔接点、光纤光栅、激光雷达/激光器(LiDAR/Laser)、光纤陀螺(FOG)等精密组件提供定制化涂覆方案,保障机械强度与信号稳定性。

核心参数如下:

涂覆长度:20mm/25mm/54mm/108mm/150mm(五档可调,兼容超短至超长涂覆需求);

涂覆直径:180μm-1000μm(全尺寸覆盖,含保偏/微纳等特种光纤)

2、双路注胶系统光纤涂覆机HXGK-T02(DIN)

一套主机配置一套模组,长度20mm、25mm、54mm、108mm可任选1种。再涂覆直径180um-1000um可任选1种。同时配置两套注胶系统,可同时兼容高、低折射胶水,无需清理管路。

第四大系列:特殊用途光纤涂覆机技术进步日新月异,助力科研不忘初心!在技术快速迭代的背景下,制造设备需紧跟发展趋势。针对国内外用户多样化的科研定制化需求,我司秉持科研赋能初心,依托全产业链自主可控的核心优势,以不计成本的投入深度响应客户需求,成功开发出系列特种光纤涂覆机定制化解决方案。方案覆盖小型化设计、户外便携电池供电、模块化分离架构、超细纤维动态飞秒对准等前沿技术路径,精准适配不同科研场景的专项需求。

1、HXGK-TM09轻量化光纤涂覆机

涂覆直径范围 195μm – 1000um;涂覆长度 4mm - 50mm(可调)。

体积小巧,重量轻,可外接电池,便于携带与移动,适合实验室、现场作业及户外环境。0μm(支持定制)

第五大系列:进口涂覆机的维修与升级改造我司自研光纤涂覆机对进口涂覆机整机和零配件均可进行平替,无缝衔接产线生产需求,设备采用模块化设计,更换简便,售后维修响应迅速。提供进口设备涂覆模组石英玻璃更换(涂层损耗、玻璃破碎、芯径变更):

提供vytran光纤涂覆机得卤素灯更改为led系统。

1、更换原uvrb固化系统为LED固化系统。

2、(可选):更换新的玻璃片。提供进口原装涂覆模组,再涂覆直径200um到900um任选。进口涂覆机的涂覆玻璃模组更换效果。

维修后的进口涂覆机,效果优于原装设备。玻璃平整度高,玻璃受力更均衡,寿命更久。

胶水线性流动,避免大量溢出,槽体更圆润,涂覆效果更好。质量稳定,与我司国产涂覆机通用,价格不到进口一半,服务时效更快,没有附加条件。

光纤涂覆机核心配件及耗材1、额外适配得涂覆模组整件。已调试并测试合格的模组,可整体拆卸并更换主机上已有得模组组件。

2、涂覆模组石英玻璃(深度镀膜加厚涂层)。微米级别高精度水刀切割、光定制的进口半球头金刚研磨刀、光刻技术等。确保玻璃外形规格精准,中心槽圆润、光滑、芯径标准且没有崩边与缺口。

多层次镀膜技术。同时上线多款镀膜机,对石英玻璃进行深度镀膜,确保镀膜层牢固不易脱落,增强耐磨损性,大幅提高使用寿命。

光学校准,激光调平检测。对石英玻璃进行严格检验,使其满足近乎严苛的验收标准。

3、各类涂覆机专用胶水。

1、进口低折射率胶水DF-016:具有低折射率和 非常低的雾度。液态折射率1.363,固化折射率1.370。

2、进口低折射率光纤胶水PC370LD:韩国LUVANTIX公司 低 折 射 率 光 纤 涂 覆 树 脂,一种低折射率含氟光纤涂料,折 射率可低达 1,37-1,40。

3、进口高折射率胶水DSM950-200 from ÅngstromBond® :折射率:1.55。

4、我司自研国产胶水。

我司自研光纤涂覆机11大技术优势

A、线性注胶。注胶不漫溢,而是沿着中心槽线性流动:节约胶水、便于清洁、贴合紧密、寿命更久。B、操作简单、效率高。一分钟完成操作,高折射胶水1s固化,低折射胶水7s固化。

C、兼容高、低折射率涂覆材料。

D、带状光纤、常规光纤及保偏光纤均适用。

E、规格型号全面。180um,200um,280um,300um,400um,430um,560um,600um,700um,860um,900um、1000um 。

F、支持定制化。

G、子系统分离、模块化设计。

H、自适应稳压注胶系统。

I、气泡隔绝与滤除系统。

J、设计、生产高标准镀膜石英玻璃。

K、高性价比。核心技术多点突破,与国际先进水平相当,国产化率100%。

光纤涂覆机是基于华纤光科在智能制造领域的深厚开发经验,融合了步进电机控制技术、自动化控制技术、集成电路设计与集成系统、模块化结构设计、光学玻璃精密切割技术、多层次深度校准镀膜技术于一体,成为了一款拥有“黄金内核”、能与进口同类产品同台竞技,并打破垄断的国产高技术全新产品。

结语华纤光电科技致力于做到:提供大、小芯径光纤热剥、切割、熔接、涂覆一站式服务。支持各类特种光纤、异形光纤、带状光纤等涂覆机的定制业务,全面满足国内外各种光纤的涂覆需求,做到自由定制,随“芯”所“遇”。

生产厂家:潍坊华纤光电科技有限公司

产地:中国.山东.潍坊

Introduction of HXGK Series Fiber Coating Machines (2025 Revised Edition)In 2025, Weifang Huaxian Optoelectronic Technology Co., Ltd. comprehensively upgraded its fiber coating machine product line and grandly launched five major series of fiber coating machines. These products are widely applicable to the coating requirements of conventional fibers, special fibers, fluorescent fibers, luminescent fibers, and various new materials such as fine fibers, and are at the international leading level in terms of technology.

The first series is the single-module fiber coating machine, which is precise and efficient.

The second series is the dual-module fiber coating machine, which has excellent performance.

The third series is the dual-channel glue injection system fiber coating machine. As an export-grade product, it is equipped with a dual-system backup and solid-state encapsulation technology, designed for 10 years of maintenance-free operation, ensuring worry-free use.

The fourth series is the special-purpose fiber coating machine, which covers a variety of customized solutions such as miniaturization, outdoor portable battery, modular separation, and ultra-fine fiber femtosecond alignment to meet specific needs.

The fifth series focuses on the maintenance and upgrade services of imported coating machines, which are professional and reliable.

The fiber coating machines support multiple control modes, including fully automatic mode, semi-automatic mode, and a hybrid fully automatic/semi-automatic mode, providing flexibility and convenience.

The fiber coating length options are diverse, covering various specifications such as (ultra-short) 20mm, (short) 25mm, (conventional) 54mm, (long) 108mm, and (extra-long) 150mm.

The fiber recoating diameter ranges from 180um to 1000um, specifically including 180um, 200um, 280um, 300um, 400um, 430um, 450um, 560um, 600um, 670um, 700um, 860um, 900um, and 1000um.

The fiber recoating shape is mainly circular. Meanwhile, customized services for special-shaped fibers such as square, ribbon-shaped, and fibers with a thin middle and thick ends are also provided to meet customers' diverse needs.

FirstSeries:Single-Module Fiber Coating Machine1.Ultra-Short Module Fiber Coating Machine HXGK-T01 (D20). (Pioneering technology)

The module length is 20mm, and the effective recoating length is 0 - 20mm. The recoating diameter can be selected from one of the values within the range of 180um - 1000um.

2.Short Module Fiber Coating Machine HXGK-T01 (D25). (Pioneering technology)

The module length is 25mm, and the effective recoating length is 0 - 24mm. The recoating diameter can be selected from one of the values within the range of 180um - 1000um.

3.Regular Module Fiber Coating Machine HXGK-T01

The module length is 54mm, and the effective recoating length is 0 - 50mm. The recoating diameter can be selected from one of the values within the range of 180um - 1000um.

4.Long Module Fiber Coating Machine HXGK-T01 (L)

The module length is 108mm, and the effective recoating length is 0mm - 100mm. The recoating diameter can be selected from one of the values within the range of 180um - 1000um.

5.Extra-Long Module Fiber Coating Machine HXGK-T150MM

The module length is 156mm, and the effective recoating length is 0mm - 150mm. The recoating diameter can be selected from one of the values within the range of 180um - 1000um.

The extra-long distance coating can reach up to 150mm. The dual glue injection heads can work independently or simultaneously. Independent operation enables short-distance coating, and simultaneous operation doubles the efficiency. The dual glue injection system allows the installation of glues with different refractive indices at the same time, eliminating the need to change the glue and ensuring seamless operation.

6.Multi-Module in One Machine

The single-module fiber coating machine can also adopt the multi-module in one machine mode, that is, one main unit is configured with multiple modules, and the required module assembly needs to be manually replaced during use. Multiple recoating diameters within the range of 180um - 1000um can be selected.

Second Series: Dual-Module FiberCoating Machine(Global Premiere)1.Short Module Fiber Coating Machine HXGK-T02 (D)

One main unit is configured with two modules, each with a length of 25mm, and the effective recoating length is 0mm - 24mm. Two recoating diameters can be selected from the range of 180um - 1000um.

2.Regular Module Fiber Coating Machine HXGK-T02

One main unit is configured with two modules, each with a length of 54mm, and the effective recoating length is 0mm - 50mm. Two recoating diameters can be selected from the range of 180um - 1000um.

3.Long Module Fiber Coating Machine HXGK-T02 (L)

One main unit is configured with two modules, each with a length of 108mm, and the effective recoating length is 0mm - 100mm. Two recoating diameters can be selected from the range of 180um - 1000um.

4.Mixed Module Fiber Coating Machine HXGK-T02 (LD)

One main unit is configured with two modules, and two lengths can be selected from 20mm, 25mm, 54mm, and 108mm. Two recoating diameters can be selected from the range of 180um - 1000um.

Weifang Huaxian Optoelectronic Technology Co., Ltd. officially released the world's first multi-model dual-channel glue injection system fiber coating machines (models: HXGK-ST06/HXGK-T150MMextra-long customized/HXGK-T02DIN), breaking industry barriers with independent core technologies and redefining the standards of fiber coating processes. As export-grade products, they are equipped with a dual-system backup and solid-state encapsulation technology, designed for 10 years of maintenance-free operation, ensuring worry-free use.

1.Flagship Model: HXGK-ST06

World's first dual-channel glue injection system: The independent dual channels support the immediate use of A/B glues, eliminating the need for cleaning and minimizing downtime. A single device can double the production capacity, meeting both laboratory and mass production requirements.

Deep scene adaptation: It provides customized coating solutions specifically for precision components such as fiber fusion joints, fiber Bragg gratings, LiDAR/lasers, and fiber optic gyroscopes (FOG), ensuring mechanical strength and signal stability.

Core parameters are as follows:

Coating length: 20mm/25mm/54mm/108mm/150mm (five adjustable levels, compatible with ultra-short to extra-long coating requirements);

Coating diameter: 180μm - 1000μm (full-size coverage, including special fibers such as polarization-maintaining and micro-nano fibers)

2.Dual-Channel Glue Injection System Fiber Coating Machine HXGK-T02 (DIN)

One main unit is configured with one module, and one length can be selected from 20mm, 25mm, 54mm, and 108mm. One recoating diameter can be selected from the range of 180um - 1000um.

It is also equipped with two glue injection systems, which can be compatible with high and low refractive index glues simultaneously, eliminating the need to clean the pipelines.

Fourth Series: Special-Purpose Fiber Coating MachineWith the rapid progress of technology, we remain committed to supporting scientific research! Against the backdrop of rapid technological iteration, manufacturing equipment needs to keep up with the development trend. In response to the diverse customized research needs of domestic and foreign users, our company adheres to the original intention of empowering scientific research.

Relying on the core advantage of independent control over the entire industrial chain, we have made cost-irrelevant investments to deeply meet customer needs and successfully developed a series of customized solutions for special fiber coating machines. These solutions cover cutting-edge technical approaches such as miniaturized design, outdoor portable battery power supply, modular separation architecture, and dynamic femtosecond alignment of ultra-fine fibers, precisely adapting to the specific requirements of different research scenarios.

1.HXGK-TM09 Lightweight Fiber Coating Machine

The coating diameter range is 195μm - 1000um; the coating length is adjustable from 4mm to 50mm.

It is compact in size, lightweight, and can be connected to an external battery, making it easy to carry and move. It is suitable for laboratories, on-site operations, and outdoor environments.

Core Accessories and Consumables of Fiber Coating Machines1.Additional adaptable coating module assemblies. The modules that have been debugged and tested qualified can be disassembled as a whole and replace the existing module components on the main unit.

2.Coating module quartz glass (deeply coated with thickened layers). It is processed using micron-level high-precision water jet cutting, custom-made imported hemispherical diamond grinding tools, photolithography technology, etc. to ensure the precise shape specification of the glass, a smooth and round central groove, standard core diameter, and no chipping or notches.

3.Special glues for various coating machines

Imported low refractive index glue DF-016:It has a low refractive index and very low haze. The liquid refractive index is 1.363, and the cured refractive index is 1.370.

Imported low refractive index fiber glue PC370LD: It is a low refractive index fiber coating resin from LUVANTIX, South Korea, a low refractive index fluorine-containing fiber coating with a refractive index as low as 1.37 - 1.40.

Imported high refractive index glue DSM950-200 from ÅngstromBond®: The refractive index is 1.55.

Self-developed domestic glues of our company。

Fifth Series: Maintenance and Upgrade of ImportedCoating MachinesOur self-developed fiber coating machines can be used as direct replacements for both the whole imported coating machines and their spare parts, seamlessly meeting the production line requirements. The equipment adopts a modular design, making replacement easy and ensuring a rapid after-sales maintenance response.

We provide services for replacing the quartz glass of imported equipment coating modules (for coating loss, glass breakage, core diameter change):

We also provide services for changing the halogen lamps of vytran fiber coating machines to LED systems.

1.Replace the original uvrb curing system with an LED curing system.

2.(Optional): Replace the glass sheet. Imported original coating modules are provided, and the recoating diameter can be selected from 200um to 900um. The effect of replacing the coating glass module of the imported coating machine.

The imported coating machines after maintenance perform better than the original equipment. The glass has high flatness, more balanced stress, and a longer service life. The glue flows linearly, avoiding excessive overflow. The groove is rounder, resulting in better coating effects. With stable quality, it is compatible with our domestic coating machines, costs less than half of the imported ones, offers faster service, and has no additional conditions.

ConclusionHuaxian Optoelectronic Technology is committed to providing one-stop services for thermal stripping, cutting, fusion splicing, and coating of large and small core diameter fibers. We support the customization of coating machines for various special fibers, special-shaped fibers, ribbon fibers, etc., fully meeting the coating requirements of various fibers at home and abroad, enabling free customization to meet all needs.

Manufacturer: Weifang Huaxian Optoelectronic Technology Co., Ltd.

Place of Origin: Weifang, Shandong, China